Day 2 for EW/FTMBAs. Day 3 for Undergraduates

Hardware prototyping is the process of making your mechanical solutions tangible. There can be a variety of goals for your hardware prototyping:

- Test market demand – do your customers want to pay for this solution?

- Form – do your customers like and understand why your solution is the way it is? Do they like the design? You can extract your target stakeholder behavioral feedback on product form through a “looks-like” prototype.

- Function – does your prototype solution perform the job(s) it was designed to execute? You can extract your target stakeholder behavioral feedback on product function through a “works-like” prototype.

- Feasibility – can we actually build a solution that meets one or more of the above objectives?

In the context of Hands-on Rapid Prototyping, the main goal is to determine if there is market interest in your mechanical solutions to physical problems. Form and function are all R&D efforts that are aligned with technical feasibility, in that we may all want the solution…but it may not be possible to build. For example, the microwave for cooling off objects:

The first time the teaching team encountered this concept was during Chris’s Fulbright experience in Madrid, Spain from a friend. They had effectively simulated a “rapid beverage cooling” machine by putting their “soda” in the “cooling microwave” for 30 seconds and next thing you know, the beverage was frosty and ready to drink. This “market experiment” for a physical product was genius as it clearly and quickly articulated the value proposition and they quickly had people “loving” the idea and “sharing” their video. But…

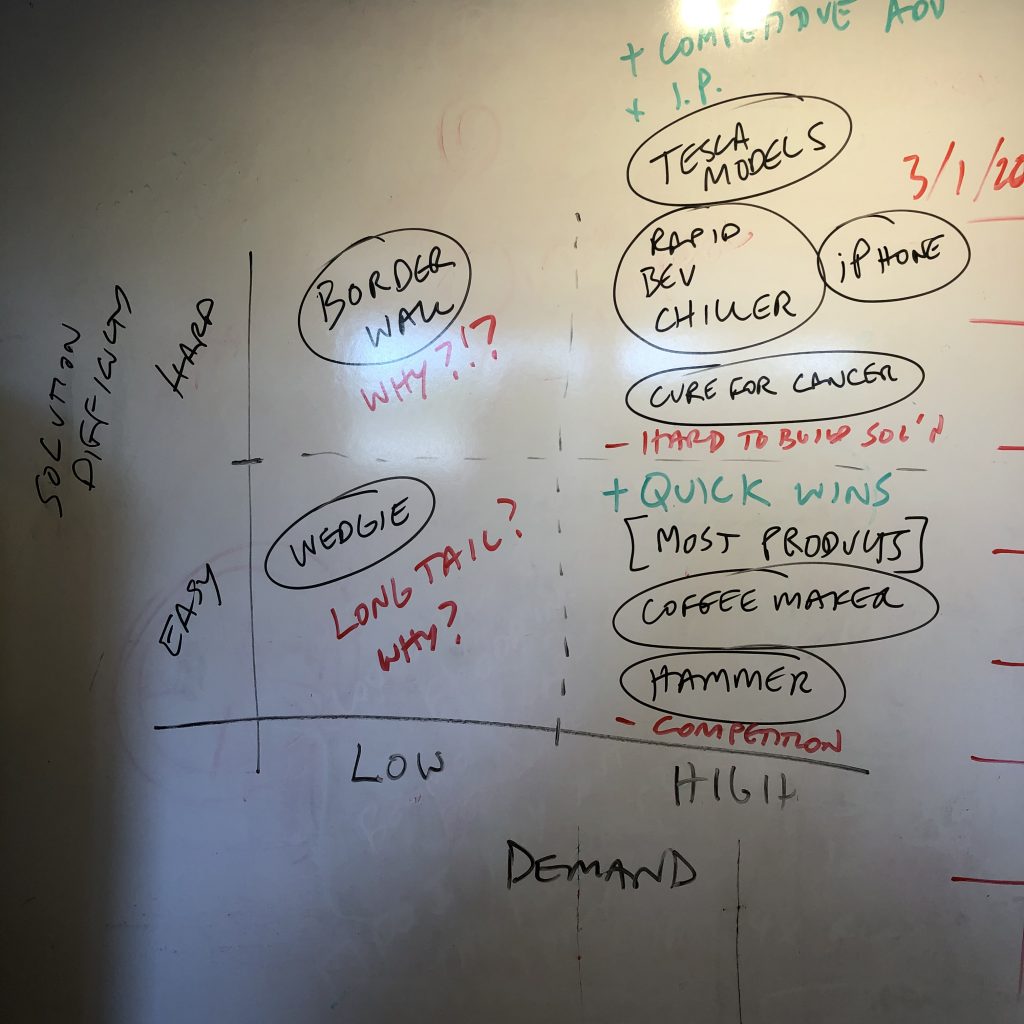

The key challenge here is that there was no quick or easy laws of physics to exploit in order to make this value proposition possible, feasible. Thus they had tapped into obvious demand. Here’s a quick two-by-two that illustrates opportunities as it relates to market demand and technical feasibility:

Technical Feasibility vs. Known Market Demand 2×2

Innovators who can solve challenging technical problems and combine that with a strong and non-obvious market need, have the potential for blockbuster success. Companies that find huge a untapped market need and pair it with a technically challenging–yet functional solution, transform society. Google, Facebook, iPhone, Dropbox, Amazon AWS, etc.

In the context of this course though, we aren’t too concerned you find a blockbuster hit. Rather, we care much more that you imbed the mindsets, tools and RIC process into your product development process.

We break down hardware prototyping tools into the following buckets:

- Office Hacking – Use whatever is available – LOW FIDELITY

- You have < 4 hours to build a physical prototype. E.g. you get a 15 minute meeting with your CEO to explain your new product concept to at 4pm the same day. How do do this? Office Hacking.

- 24 Hour Prototyping – Use tools, DIY – MEDIUM FIDELITY

- With 24 hours instead of just a handful, you can dramatically improve your prototype fidelity using rapid prototyping tools like, sketching, CAD, 3D printing, laser cutting and other quick turn fabrication tools. E.g. imagine the meeting above with your CEO went well, they want you to come present to the senior management the next day at 4pm. What do you do?

- 48 Hour Prototyping – Use services, Outsource – HIGH FIDELITY

- Adding another 24 hours to your hardware prototyping journey enables more options for you to dramatically improve your prototype fidelity. Now you can use rapid prototyping services like You3Dit.com, Protolabs.com and others to transform your CAD design into real, physical parts using advanced machines and materials.

In general, as an entrepreneur, you’re always working to manage and mitigate risk. Time and money are crucial resources. High levels of prototype fidelity OR product quality require both lots of time and money. Here’s an often cited “manufacturing triangle” of manufacturing speed, quality and cost…and how you can typically have only 2/3 that you want at any given time:

Thus, when you don’t know if you have any market demand, it’s best to come up with a prototype that you believe you can “sell” to a prospect customer while keeping costs and development times low.

Looks-Like / Works-Like Prototypes

Looks-like prototypes help your target stakeholders understand what your product might look like, feel like; understand their response to the product form. How big is the product? How much does it weigh? What color(s)? What does it feel like?

Works-like prototypes help your target stakeholders understand how the product will function. What job it does for your target stakeholder and how the product works (or doesn’t work). The goal with a works-like prototype is to actually get the technology to work and then see how your users will achieve their goals with this working prototype (working hard to ignore / disregard any lack of polish or aesthetic refinement)

Combination – once you have strong positive engagement and feedback based on your works like, looks like prototyping efforts, then you can consider combining the two creating a “beta prototype”; a prototype that is nearing completion of the prototyping stage and ready to enter the beginnings of manufacturing and assembly.

Frankensteining – taking existing technology and mixing and matching in order to create something new, useful and non-obvious. For example, these truck bed lights were “invented” by combining 5V, 1A USB LED lights with an Anker 10000 kWh portable smartphone battery charger:

References: